powdr haearn carbonyl

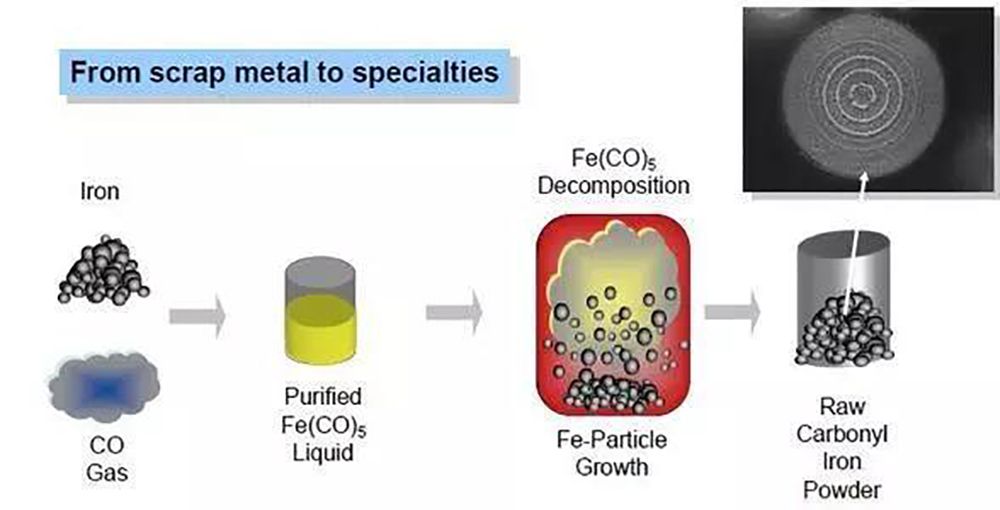

Disgrifiad o'r Cynnyrch

Mae powdr haearn carbonyl yn fath o bowdr metel mân iawn, sydd â nodweddion purdeb uchel, hylifedd da, gwasgariad da, gweithgaredd uchel, priodweddau electromagnetig rhagorol, ffurfiant gwasgu a sintro da.Defnyddir powdr haearn carbonyl yn eang mewn meysydd milwrol, electroneg, cemegol, meddygaeth, bwyd, amaethyddiaeth a meysydd eraill.Gellir paratoi powdr haearn carbonyl i wahanol ffurfiau megis ffibr, fflawiau neu bêl yn unol â'r gofynion i ddiwallu gwahanol anghenion cwsmeriaid.

Manyleb

| Eitem | Cyfansoddiad Cemegol | Eiddo Corfforol | |||||||

| Fe | C | N | O | AP.Dwysedd | Tap Dwysedd | Maint Gronyn Laser | |||

| ≥ % | ≤% | ≥ | ≥ | Ch10 | D50 | D90 | |||

| HR1-1 | 98 | 0.8 | 0.6 | 0.4 | 2.2 | 4 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR1-2 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.9 | 0.6-1.5 | 2.0-3.0 | 4.5-8.0 |

| HR1-3 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.8 | 1.0-3.0 | 3.0-5.0 | 5.0-12.0 |

| HR1-4 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 1.5-3.5 | 5.0-6.0 | 11.5-16.5 |

| HR1-5 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.0-4.0 | ≥6.0 | 44915 |

| HR1-6 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 4 | 1.5-2.5 | 3.0-4.0 | 5.5-8.5 |

| HR1-7 | 98 | 0.8 | 0.7 | 0.4 | 2.5 | 4 | 2.0-3.6 | 4.0-5.0 | 7.0-11.0 |

| HR1-8 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.6-4.0 | 5.0-6.0 | 11.5-14.5 |

| HR2-1 | 99.5 | 0.05 | 0.01 | 0.3 | 2.5 | 3.8 | 0.58-1.5 | ≤3.0 | 4.5-8.0 |

| HR2-2 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 0.9-3.0 | 3.0-5.0 | 5.5-12.0 |

| HR2-3 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 1.5-3.0 | 5.0-8.0 | 10.0-18.0 |

| HR2-4 | 99.5 | 0.1 | 0.05 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-5 | 99.5 | 0.4 | 0.2 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-6 | 99.5 | 0.05 | 0.01 | 0.4 | 2.5 | 3.8 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR2-7 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 1.5-3.0 | 3.0-5.0 | 5.5-11 |

| HR2-8 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 2.0-3.5 | 5.0-8.0 | 10.0-15.0 |

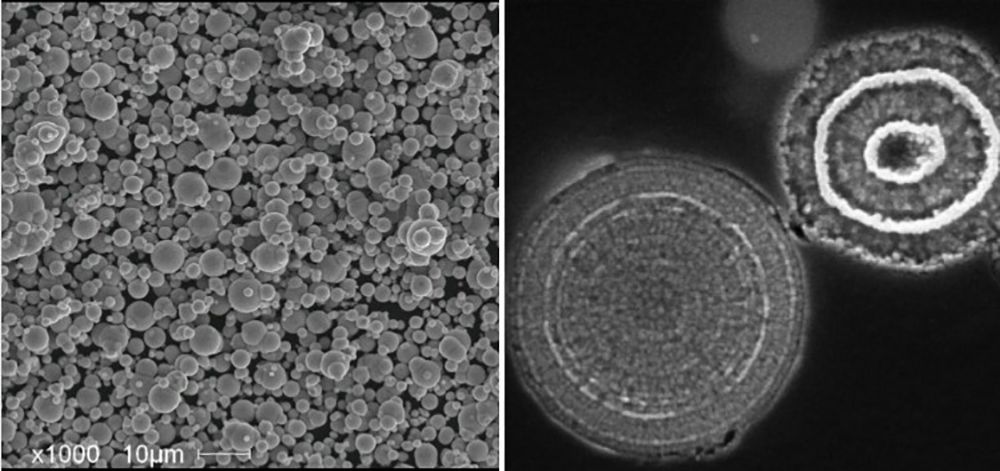

Sem

Mantais

purdeb cemegol 1.High

Priodweddau electromagnetig 2.Excellent

3.Spherical

gronynnau, strwythur croen winwnsyn

4.0.1-10 micron gronyn cynradd

5.High flowability, dispersibility a chysondeb

6.Hgh gweithgaredd, cywasgedd ac eiddo sintering rhagorol