Ychwanegyn Gweithgynhyrchu Dur Di-staen Powdwr 316l ar gyfer Argraffu 3d

Disgrifiad o'r Cynnyrch

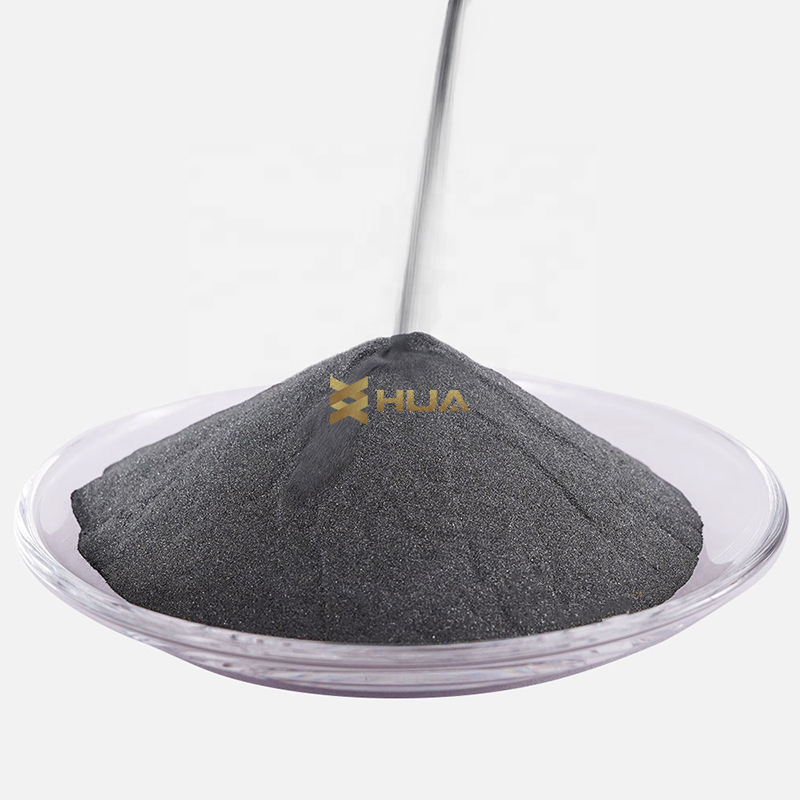

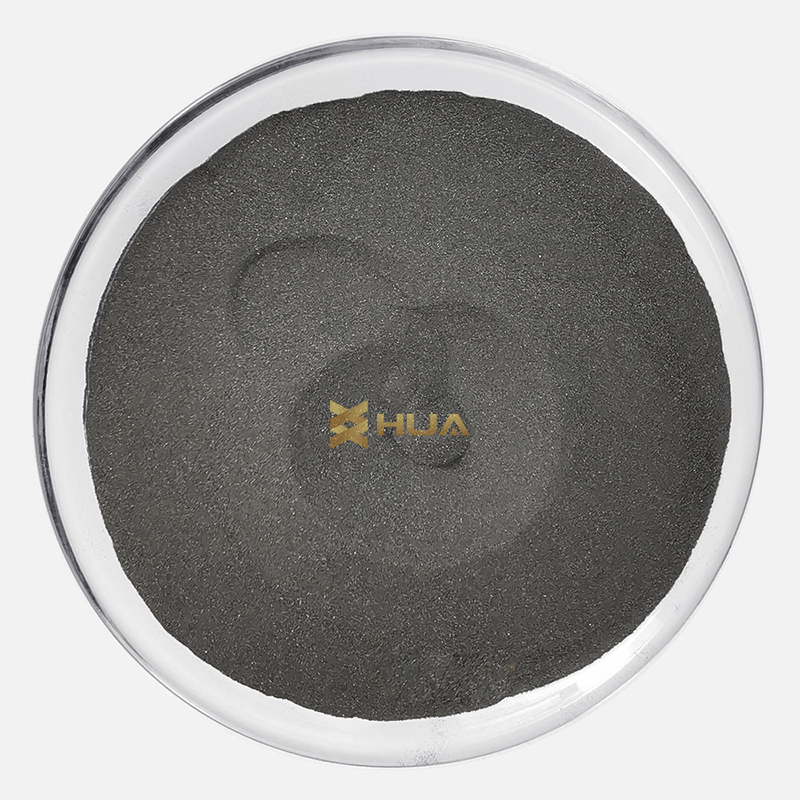

Gwneir powdr dur di-staen trwy broses atomization dŵr ac mae ganddo ymwrthedd cyrydiad da a gwydnwch.Mae gan bowdr dur di-staen ystod eang o ddefnyddiau diwydiannol.

Darparu amrywiaeth o bowdr metel dur di-staen gyda maint gronynnau gwahanol.

Yn ôl defnydd

Gwasgu Isostatig 1.Hot

Mowldio Chwistrellu 2.Metal

Argraffu 3.3D

Chwistrellu 4.Thermal

Yn ôl y broses gynhyrchu

1.Water atomization

2.Water nwy cyfunol atomization

3.Gas atomization

4.Vacuum atomization

Manylion y fanyleb

| Cyfansoddiad powdr dur Stainess % | |||||||||

| Gradd | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Cais

Gellir defnyddio powdr dur di-staen ar gyfer chwistrellu thermol, meteleg powdr, sintering wasg meteleg powdwr (PM), hidlydd sintro mowldio chwistrellu (MIM), ac ati, cynnwys ocsigen atomization dŵr<4000PPM, atomization nwy<1000PPM.

Mantais powdr dur di-staen HUARUI

● Hyd yn oed cyfansoddiad powdr, llai o amhureddau

● Sphericity uchel

● Cynnwys ocsigen isel

● Hylifedd da

● Dwysedd rhydd uchel, dwysedd tap uchel

● Llai o bowdr gwag, llai o bowdr lloeren

System rheoli ansawdd

Mae gan 1.Huarui system rheoli ansawdd llym.Rydym yn profi ein cynnyrch yn gyntaf ar ôl i ni orffen ein cynhyrchiad, ac rydym yn profi eto cyn pob dosbarthiad, hyd yn oed sampl.Ac os oes angen, hoffem dderbyn trydydd parti i brofi.Wrth gwrs, os dymunwch, gallem ddarparu sampl i chi ei brofi.

2.Our ansawdd cynnyrch yn cael ei warantu gan Sichuan Metallurgical Institute a Guangzhou Sefydliad Ymchwil Metel.Gall y cydweithrediad hirdymor gyda nhw arbed llawer o amser profi i gwsmeriaid.